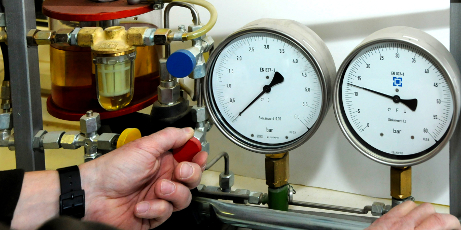

Baugrundinstitut Franke-Meißner has a well-equipped soil-mechanical laboratory at the company headquarters in Wiesbaden. As part of project execution, the employees (graduate engineers/graduate geologists/construction materials testers/drilling machine operators/technicians) carry out drilling, sounding and sampling operations, field tests, metrological examinations as well as laboratory tests and other check tests.

Well-equipped equipment buses, multiple all-terrain vehicles and two transport crawlers that ensure the required flexibility all year round and even under difficult operating conditions are available for performing the fieldwork-

In addition to the sample storage and equipment rooms, the laboratory also accommodates the test stands for the classic soil-mechanical tests. The employees can also draw on equipment and measuring methods that were developed in-house.

Due to decades of experience in quality monitoring in groundwork, landfill and tunnel construction,

BFM not only has the expertise, but also extensive mobile equipment for setting up construction site laboratories on site.