Special civil engineering services

- Project-specific assessment of the necessity and applicability of the method and indication of execution and cost risks, possibly presentation of alternatives

- Cost estimates and/or cost comparison for differing methods

- Geotechnical planning of the measure, including the execution of the required stability verifications

- Drawing up and supervision of the quality assurance plan

- Specialist construction supervision in the implementation phase

- Drawing up or check of the bidding documents

- Any required technical supervision of the licensing process

BFM Services

- Execution and assessment of the building site conditions

- Indication of optimum values for skin friction and point resistance for various pile systems

- Planning of pile foundations, including static verifications, formwork and structural drawings

- Prediction of the load-subsidence behaviour of pile foundations and pile groups as well as combined pile/raft foundations

- Deformation calculations on pile foundations with conventional calculation methods or the finite element method

- Drawing up of cost estimates on the basis of current market prices

- Optimisation of pile foundations according to technical and economic criteria

- Preparation and check of bidding documents, including detailed bills of quantities

- Technical supervision of the manufacturing of the piles, definition and supervision of the manufacturing criteria regarding the carrying capacity, e.g. of special piles, during construction, planning, calling for tenders, supervising and evaluating test loads for piles

- Check of the integrity of the piles using what is known as the “low strain” method

Experience

BFM’s range of experience includes the execution of all types of piles and foundation systems that are similar to piles; see also the topics of soil improvement and combined pile/raft foundation

- Bored piles according to DIN EN 1536/DIN 4014

- Micropiles (known as GEWI piles) according to DIN EN 14199/DIN 4128

- Ram piles made of cast-in-place concrete, e.g. Franki piles, Simplex piles

- Palisades, barrettes

- Special piles from various providers (e.g. FUNDEX, VIBREX, ATLAS types)

- Special piles for rehabilitating foundations, e.g. ERKA type

- Steel piles, ductile piles and vertically loaded sheet piles

Special civil engineering

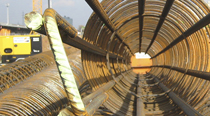

The use of modern special civil engineering techniques is increasing in the execution of civil engineering work in densely built-up city centres, in part due to the stringent deformation restrictions regarding the surrounding neighbouring building development. This applies to excavation pits and foundations and also to underground structures, such as tunnels for underground and suburban trains. The use of special civil engineering methods in their border area often leads to delays in construction and cost increases. This is why the need for competent technical consulting is particularly high here.

BFM provides consulting services on the basis of knowledge of the methods as well as extensive practical experience in the economically successful use of special civil engineering methods.

Our institute offers consulting and planning services on the special civil engineering techniques listed below:

- All types of pile foundations (e.g. bored and displacement piles)

- Permanent soil anchors, soil nails, etc.

- Diaphragm and cut-off walls, sheet-pile walls

- Two-dimensional and pile-type building site improvements (stone columns etc.)

- Injection method

- Jet grouting

- Foundation ground freezing

- Underpinning and stabilisation by means of the aforementioned methods

Combined pile/raft foundations

The composite construction of combined pile/raft foundations involves spreading the structural load to the building site through piles and a plate. Compared to a pure pile foundation according to DIN 1054, Chapter 8, the use of a plate results in great savings potential in terms of the pile manufacturing costs. This applies to bridge piles and the high-rise buildings in the city centre of Frankfurt in equal measure.

The carrying behaviour of a combined pile/raft foundation is essentially determined by the interactions between the plate, the pile and the surrounding building site. The actual load-subsidence behaviour is thus influenced significantly by the condition of the building site and the distribution and length of the piles, which results in an optimisation task for the geotechnical planner. In addition to a confident command of the numerical calculation programmes, extensive project experience as well as the project team’s detailed knowledge on the local building site conditions regarding the carrying and deformation behaviour of the piles play a decisive part in solving this task.

Our services include:

- Assessment of the building site and groundwater conditions in the field and the laboratory

- Drawing up of feasibility studies

- Drawing up of cost estimates on the basis of current market prices

- 3D calculation of the carrying and deformation behaviour of the combined pile/raft foundation using the finite element method (FEM)

- Project-specific technical/economic optimisation of the arrangement and length of the piles in consultation with the person planning the supporting structure

Technical check of the bidding documents

Technical supervision of the manufacturing of the piles - Metrological monitoring of the carrying and deformation behaviour of the combined pile/raft foundation

Special civil engineering for improving the building site

If a structure (e.g. building, dyke, etc.) is built on soil with a low carrying capacity at a depth that is relevant for the foundation, the load-dependent subsidence and subsidence differences can lead to a loss of serviceability and, in extreme cases, a loss of the stability of the structure. This can be prevented by creating a building site improvement in advance. Typical methods for this are:

- Partial or complete soil replacement (also known as: soil replacement method)

- Deep compaction (e.g. compaction by vibration and packing/compression)

- Dynamic intensive compaction (heavy drop plates)

- Injection techniques (e.g. compaction grouting)

- Jet grouting

- Consolidation method (front fill and ballast covering, vertical drains, etc.)

The central tasks of geotechnical consulting are the assessment of the various methods (selection of methods) from a geotechnical and economic perspective, followed by the dimensioning of the building site improvement, which is often based on empirical approaches combined with building site-specific experience.

Since there are no normative regulations, the economic optimisation potential is comparatively high.

Our services include:

- Assessment of the building site and groundwater conditions in the field and the laboratory

Performance of subsidence analyses according to DIN 4019

Site-specific assessment of the methods of various planning variants from a geotechnical and economic perspective (cost estimation)

Computer-assisted dimensioning of the building site improvement (e.g. according to Priebe)

2D/3D deformation calculations using the finite element method (FEM)

Waste-related classification (LAGA etc.) of any accruing excavated material

Metrological observation of the carrying and deformation behaviour of the structure and foundation

Technical supervision of the manufacturing process